Great Machines

One Common Goal

LIFT LIKE A PRO

Mini Skid Steer LOADER

LIFT LIKE A PRO

Tomcat TL-185

Tomcat Stand-On Mini Skid Steer

Track Loader TL-185

- 33" Wide x 6' 0" Long

- $22,495 MSRP

Tomcat HT-310

Tomcat Stand-On Mini Skid Steer High

Track Loader Tomcat HT-310

- 41" Wide x 7' 2" Long

- $35,495 MSRP

Tomcat WL-210

Tomcat Stand-On Mini Skid Steer Wheel Loader

Tomcat WL-210

- 42" Wide x 6' 0" Long

- $22,895 MSRP

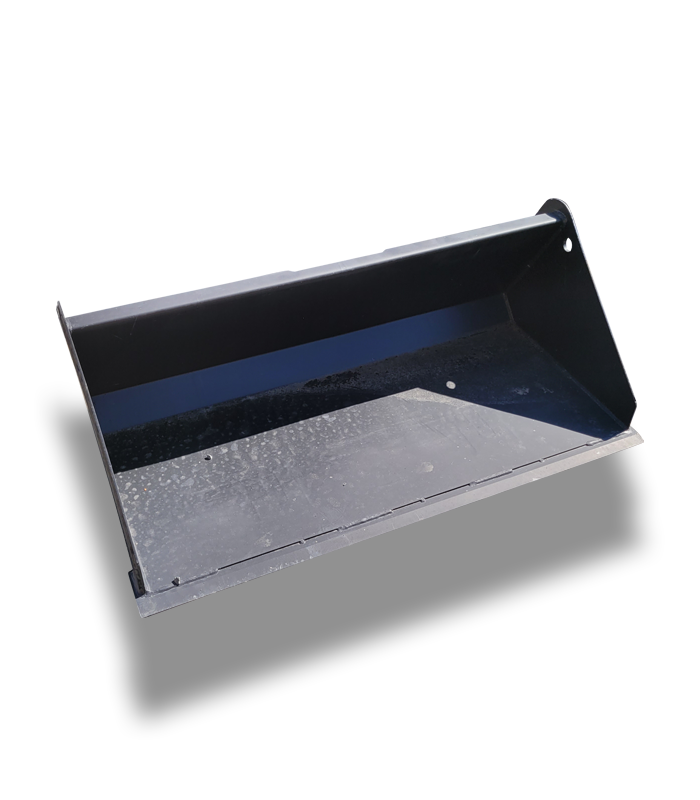

Large Selection of Attachments

A Few of the Popular

Street and Snow

Sweeper SW-48

Tomcat Street and Snow Sweeper SW -48

- 48" Wide

- $6,495 MSRP

Stump Grinder

Tomcat SG-36

Tomcat Stump Grinder SG-16

- Tomcat Stump Grinder SG-16

- $5,869 MSRP

01.

Idea & Concept

The technical support department is a dynamic team, mainly responsible for providing strong technical support for the company’s various business developments.

02.

Steel Cutting & Drilling

Quality steel plates are sourced and directly purchased in bulk. This allows us to save on costs and maintain a large supply of steel sheets for short notice large orders.

03.

Welding

The latest lifting, positioning, CNC and MIG welding equipment ensure high precision welding for all our steel parts, large and small. After all the parts are welded, they are carefully inspected to guarantee their quality and long life.

04.

Blasting

Once all parts are inspected, they are prepared for blasting. This process cleans, smooths, and removes any traces of impurities on the surface of the part, when the primer base paint is applied. After blasting, parts are inspected to guarantee a high finish.

05.

Painting Enclosure

Parts are carefully cleaned, dried, and smoothed in a controlled environment, before they are ready for painting. Once the primer base paint is applied, the same process is repeated for the surface coating. The use of high-quality painting and solvents allows us to guarantee an excellent finish.

06.

Assembling

All parts including the axles, frames, engine systems, electronic systems, cabins, etc., are installed here to create the final assembly. Throughout this process, each work station is carefully supervised and monitored by our qualified engineering technicians and by our chief equipment manufacturing engineers.

07.

Testing

Once the machines have been assembled, they go through rigorous examination and testing. This guarantees each machine’s high performance.

08.

Loading & Delivery

Before they are delivered, the machines are washed, dried, and prepared to be professionally loaded. This ensures that our customers always receive their machines in top condition.

DEALER LOCATOR

You want the World’s Fastest Lawn Mower at one of those “big box” stores: all of our dealers are locally-owned independent business, and they are as diverse as the communities they serve. Find your local dealer today.